Lintlha tsa mantlha tse lokelang ho nahanoa setšoantšong sa moralo oa polokelo e batang li kenyelletsa lintlha tse 5 tse latelang:

1. Moralo oa khetho ea sebaka sa polokelo e batang le ho fumana boholo ba polokelo e batang e etselitsoeng.

2. Lintho tse bolokiloeng polokelong e batang le litlhoko tsa lebelo la ho pholisa tsa polokelo e batang.

3. Khetho ea li-compressor tsa sehatsetsing bakeng sa polokelo e batang.

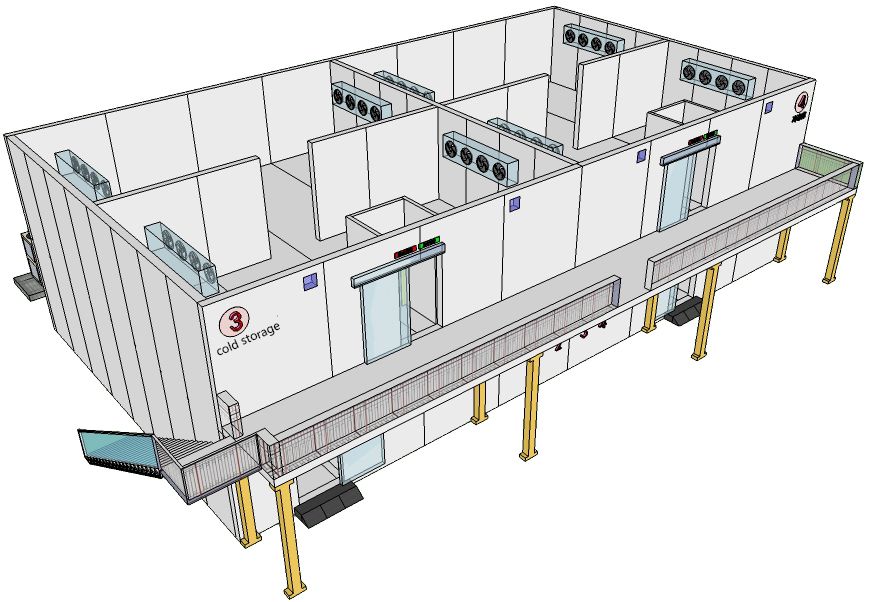

Moralo oa polokelo o batang o lokela ho ela hloko sebaka, taolo ea mocheso, tlhophiso ea li-unit, joalo-joalo tsa cpolokelo ea khale.

Ka kakaretso, polokelo e batang e nyane le e mahareng e na le letoto la melemo e kang nako e khuts'oane ea ho kenya, ts'ebeliso e potlakileng le e sebetsang, theko e ntle le e theko e tlase, joalo-joalo, e 'nileng ea amoheloa ka potlako ke mmaraka mme e sebelisitsoe haholo liindastering tse ngata, joalo ka mabenkele a maholo, lihotele, masimo le lithupelo tsa tlhahiso ea lijo. Lipetlele, likhemisi, joalo-joalo.

Joale u etsa moralo oa moralo oa polokelo e batang joang? Ke lintlha life tse lokelang ho tsejoa moralong oa boenjiniere ba polokelo e batang e le hore moralo oa moralo o ka hlakisoa kapele?

1. Moralo oa khetho ea sebaka sa polokelo e batang le ho fumana boholo ba polokelo e batang e etselitsoeng.

Khetho ea sebaka sa polokelo e batang le ho lokisoa ha moralo oa polokelo e batang le tsona li lokela ho nahanela meaho le lisebelisoa tse tlatselletsang tse hlokahalang, joalo ka lithupelo, liphaposi tsa ho paka le tsa ho qetela, matlo a polokelo ea lisebelisoa le sethala sa ho laeloa le ho laolla. Tlhokomelo e khethehileng: Haeba sebaka sa marang-rang se na le litlhoko tsa ho thibela ho phatloha, ka kopo latela ka tieo litlhoko tse nepahetseng tsa ho thibela ho phatloha ha ho phatloha ha lisebelisoa.

Khetho ea sebaka sa polokelo e batang le ho lokisoa ha moralo oa polokelo e batang le tsona li lokela ho nahanela meaho le lisebelisoa tse tlatselletsang tse hlokahalang, joalo ka lithupelo, liphaposi tsa ho paka le tsa ho qetela, matlo a polokelo ea lisebelisoa le sethala sa ho laeloa le ho laolla. Tlhokomelo e khethehileng: Haeba sebaka sa marang-rang se na le litlhoko tsa ho thibela ho phatloha, ka kopo latela ka tieo litlhoko tse nepahetseng tsa ho thibela ho phatloha ha ho phatloha ha lisebelisoa.

Ho kenngoa ha polokelo e nyenyane ea serame ho ka ba ka hare kapa ka ntle, 'me litšenyehelo tsa ho kenya ka hare ho ntlo li batla li le tlaase ho feta tsa ho kenya ka ntle.

Ho ea ka mofuta oa tšebeliso, polokelo e batang e ka aroloa ka mekhahlelo e meraro:kabo polokelo batang, mabenkele a ho boloka a batang, le tlhahiso ea polokelo batang.

Polokelo e batang e behang litholoana e hahiloe sebakeng sa tlhahiso moo phepelo ea thepa e batlang e tsepame, 'me lintlha tse kang lipalangoang tse loketseng le ho hokahana le mmaraka le tsona li lokela ho shejoa.

Ho lokela hore ho be le maemo a matle a metsi ho potoloha polokelo e batang, boemo ba metsi a ka tlas'a lefatše bo be tlase, ho molemo ho ba le karohano tlas'a polokelo e batang, 'me moea o motle o lokela ho bolokoa. Ho boloka o omme ho bohlokoa haholo bakeng sa polokelo e batang. Bophahamo ba polokelo e batang Boholo ba polokelo e batang bo lokela ho raloa ho latela boholo ba lihlahisoa tsa temo tse lokelang ho bolokoa selemo ho pota. Bokhoni bona bo baloa ho ipapisitsoe le boholo boo sehlahisoa se bolokiloeng se tlamehang ho lula ho sona polokelong e batang, hammoho le li-aisles lipakeng tsa mela, sebaka se pakeng tsa qubu le lebota, siling le lekhalo lipakeng tsa sephutheloana. Ka mor'a ho fumana bokhoni ba polokelo e batang, fumana bolelele le bolelele ba polokelo e batang.

Mong'a polokelo e batang o tlameha ho bolella k'hamphani ea boenjiniere ba polokelo e batang lintlha tse qaqileng tsa polokelo e batang, joalo ka: bolelele, bophara le litekanyo tsa bophahamo. Ke feela ha o tseba lintlha tsena tse ikhethileng, o ka etsang lipalo tse latelang. Ho phaella moo, ho molemo ho tseba mokhoa oa ka hare kapa oa ka ntle, ho bula lifensetere bakeng sa ventilation, joalo-joalo.

2. Lintho tse bolokiloeng polokelong e batang le litlhoko tsa lebelo la ho pholisa tsa polokelo e batang.

Ke feela ha o hloka ho beha lihlahisoa tse khethehileng polokelong e batang re ka tsebang hore na u hloka mofuta ofe oa polokelo ea serame. Ka mohlala, mocheso le mongobo oa polokelo ea ho boloka meroho le litholoana li fapane. Esita le haeba polokelo e tšoana, lintho tse khethehileng tsa polokelo li loketse ka ho fetisisa bakeng sa mocheso o fapaneng. , Cowen le eena a ka fapana. Kenya nama ka sehatsetsing se nang le mocheso oa -18°C. Boholo ba yuniti e hlophisitsoeng bo boetse bo fapane ho latela mocheso; lebelo la ho pholisa la polokelo e nyane e batang ea hlokahala. Mohlala, ho nkuka metsotso e 30 ho fihlela mocheso o pholileng oo ke o hlokang sebakeng sena sa polokelo e batang, kapa polokelo ea hau e batang e romelloa khafetsa ho tsoa le ho tsoa. Maemong a joalo, tlhophiso ea yuniti hangata e hloka ho eketseha, ho seng joalo mocheso oa polokelo o batang o ke ke oa theoha ka potlako, ho fella ka ho senyeha ha lijo, joalo-joalo; hore na polokelo e batang ea thepa e hahiloe hakae letsatsi le leng le le leng, ts'ebetso e phahameng e tla ja ho feta, haeba ho ka hakanyetsoa ho feta, Sehatsetsi sa Yuanbao se tla rala kamore ea "buffer" bakeng sa bareki e le hore polokelo e batang e ka ba le nako e lekaneng ea ho ema letsatsi le leng le le leng, matla a eketsehileng le matla a mangata a matla.

3. Khetho ea li-compressor tsa sehatsetsing bakeng sa polokelo e batang.

Tlhophiso ea bohlokoa ka ho fetesisa ke yuniti ea mantlha ea compressor ea polokelo e batang. Li-compressor tse tloaelehileng li arotsoe ka lipiston tsa semi-hermetic, meqolo e koetsoeng ka botlalo, lipiston tse koetsoeng ka botlalo, le li-screw compressors.

Lisebelisoa tsa thepa ea sehatsetsing ea polokelo e nyane e batang e ka bang 30% ea litšenyehelo tsa kaho ea polokelo e batang.

Khetho ea Sehatsetsi Compressor Ka sesebelisoa sa sehatsetsing sa polokelo e batang, bokhoni le bongata ba compressor ea sehatsetsing li lokisoa ho ea ka mocheso o phahameng oa mocheso oa sekhahla sa tlhahiso le ho nahana ka mekhahlelo e fapaneng ea sehatsetsing. Tlhahisong ea sebele, ho ke ke ha khoneha ho lumellana ka ho feletseng le maemo a moralo. Ka hona, hoa hlokahala ho khetha le ho ikamahanya le maemo a sebele a tlhahiso ho fumana bokhoni bo loketseng le bongata ba li-compressor tse lokelang ho kenngoa ts'ebetsong, molemong oa ho sebelisa tšebeliso e tlase le maemo a loketseng ho phethela mesebetsi e hlokahalang ea sehatsetsi sa polokelo e batang.

Mefuta e tsebahalang haholo ea li-compressor brands ke Copeland, Bitzer, joalo-joalo. Litsenyehelo tsa lihlahisoa tse fapaneng li tla fapana haholo, haholo-holo marakeng a sehatsetsing le a leqhoa, ho na le li-compressor tse ngata tse nchafalitsoeng le tsa maiketsetso le li-compressor tsa copycat. Haeba bareki ba li reka, li tla sebelisoa bakeng sa tlhokomelo ea morao-rao. Tlhokomelo e baka likotsi tse kholo tse patiloeng.

Ka kakaretso, ho latela tekanyetso ea moreki, theko ea lihlahisoa tse tsoang kantle ho naha kapa tsa lapeng e tla fetoha ho isa bohōleng bo itseng. Khetho ea mokhoa oa ho futhumatsa o batang oa polokelo Khetho ea mokhoa oa ho futhumatsa o batang haholo ke khetho ea komporo ea polokelo e batang le evaporator.

Tlas'a maemo a tloaelehileng, lihatsetsi tse nyane haholo-holo li sebelisa li-compressor tse koetsoeng ka botlalo. Libaka tse batang tsa boholo bo mahareng hangata li sebelisa li-compressor tsa semi-hermetic piston; li-storages tse kholo tse batang li sebelisa semi-hermetic screw kapa lihlooho tse ngata tsa mofuta oa piston ka ho bapisa. Ka mor'a qeto ea pele, moralo oa morao-rao oa polokelo ea serame le ho kenya le tsamaiso ea ho boloka serame li ntse li le boima.

4. Khetho ea boto ea ho boloka mocheso o batang.

Khetho ea lisebelisoa tsa ho boloka mocheso o batang Ho khethoa ha lisebelisoa tsa ho boloka mocheso o batang ho tlameha ho ikamahanya le maemo a sebaka seo, e seng feela ho ba le ts'ebetso e ntle ea ho kenya mocheso oa mocheso, empa hape e be moruo le ho sebetsa. Sebopeho sa polokelo ea sejoale-joale se batang se ntse se tsoela pele ho ea polokelong e pholileng e etselitsoeng pele. Likarolo tsa polokelo tse batang tse kenyelletsang lera le thibelang mongobo le lera la ho futhumatsa mocheso li etsoa le ho bokelloa setšeng. Melemo ke hore kaho e bonolo, e potlakile ebile e ka sutheha, empa litšenyehelo li batla li phahame. Haeba moreki a se na litlhoko tse khethehileng, k'hamphani ea ho kenya polokelo e batang ka kakaretso e tla khetha boto ea polokelo e theko e boima ka ho fetisisa bakeng sa moreki. Ha e le hantle, boto ea polokelo e boetse e na le boemo bo phahameng le bo botle, 'me theko ea polokelo e nyenyane e batang e tla eketseha ka tlhaho.

Boto ea polokelo e batang e na le: polyurethane, poleiti ea tšepe ea 'mala, poleiti ea aluminium e nang le mahlakoreng a mabeli, poleiti ea tšepe e sa hloekang, botenya bo fapane le ho boloka mocheso o phahameng le ho boloka mocheso o tlaase, tse tloaelehileng ke 10 cm, 15 cm le 20 cm.

5. Monyako oa polokelo e nyenyane ea serame e lokela ho behoa ka mokhoa o utloahalang ho ea ka bophara ba tsela e ka sebelisoang setšeng.

Meetso e tloaelehileng ea menyako e kenyelletsa mamati a thellang, mamati a thellang, mamati a motlakase, mamati a thellang, mamati a selemo, joalo-joalo; E ka sebelisoa ka mokhoa o utloahalang ho latela litlhoko tsa bareki. Haeba boholo ba lipalangoang tsa thepa bo lekanyelitsoe, ho kgothaletswa ho sebelisa monyako o thellang o ka nolofatsang lisebelisoa tse kholo le ho lumella thepa e kholo ho kena le ho tsoa ka bolokolohi.

Ho phaella moo, ho na le: khetho ea tsamaiso ea pholileng ea polokelo e batang, haholo-holo khetho ea compressor le evaporator ea polokelo e batang. Tlas'a maemo a tloaelehileng, polokelo e nyane e batang haholo e sebelisa li-compressor tsa hermetic ka botlalo; polokelo e batang ea boholo bo mahareng ka kakaretso e sebelisa li-compressor tsa semi-hermetic; polokelo e kholo ea serame e sebelisa li-semi-hermetic compressors, 'me mekhoa ea condensation ea lisebelisoa tsa sehatsetsi e arotsoe ka pholileng ea moea, pholiso ea metsi le pholiso ea mouoane. Foromo, basebelisi ba ka khetha ho ea ka boemo ba 'nete, moralo oa polokelo o batang oa ho taka ho kenya polokelo le taolo e boima le ho feta.

Nako ea poso: Jun-11-2022