Tsamaisa li-Compressor Units

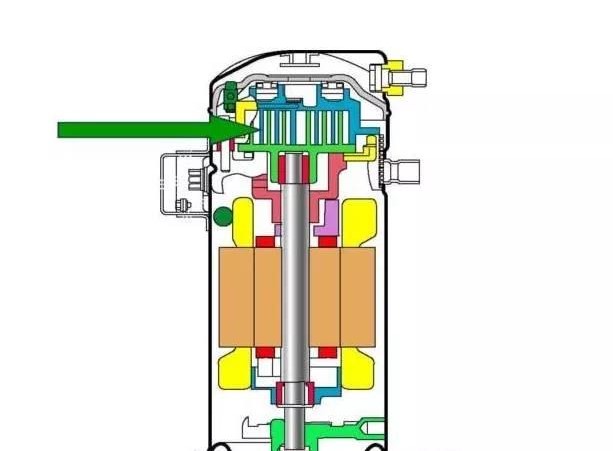

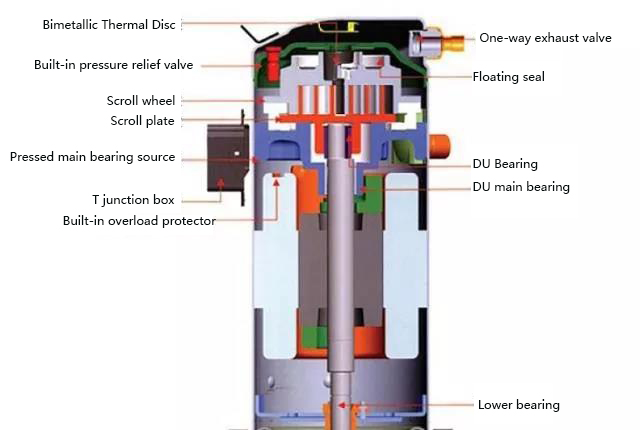

Molao-motheo:Sebopeho sa mohala oa moqolo oa poleiti e tsamaeang le poleiti e tsitsitseng e tšoana, empa phapang ea mohato ke 180∘ ho letlooa ho etsa letoto la libaka tse koetsoeng;poleiti e tsitsitseng ha e sisinyehe, 'me poleiti e tsamaeang e pota-pota bohareng ba poleiti e tsitsitseng e nang le eccentricity e le radius.Ha disk e tsamaeang e pota-pota, e phalla ka tatellano, e le hore sebaka se bōpehileng joaloka crescent se tsoele pele ho hatelloa le ho fokotseha, e le hore khase e tsoele pele ho hatelloa 'me qetellong e lokolloe ho tloha lesoba le bohareng la diski e tsitsitseng.

Sebopeho:disc e tsamaeang (vortex rotor), static disc (vortex stator), bracket, cross coupling ring, mokokotlo oa mokokotlo oa mokokotlo, eccentric shaft

Molemo:

1. The eccentric shaft e khanna moqolo o tsamaeang o ka potoloha ka lebelo le phahameng, 'me compressor ea moqolo e nyenyane ka boholo le boima bo bobebe;

2. Liphetoho tsa matla tsa likarolo tse tsamaeang tse kang moqolo o sisinyehang le shaft e kholo li nyenyane, 'me ho sisinyeha ha mochine oohle ho nyenyane;

3. E loketse ho tsamaea ka lebelo le fapaneng le theknoloji ea taolo ea lebelo la ho fetoha ha lebelo;

4. Compressor eohle ea moqolo e na le lerata le tlase haholo;

5. Compressor ea moqolo e na le tiiso e ka tšeptjoang le e sebetsang, 'me coefficient ea eona ea sehatsetsi ha e fokotsehe ka ho eketseha ha nako ea ts'ebetso, empa e eketseha hanyenyane.

6. Compressor ea moqolo e na le litšobotsi tse ntle tsa ho sebetsa.Mocheng oa mocheso oa mocheso oa moea, o bonahala ka ho khetheha ka ts'ebetso e phahameng ea ho futhumatsa, botsitso bo botle, le polokeho e phahameng;

7. The scroll compressor ha e na bophahamo ba molumo mme e ka boloka ts'ebetso e phahameng ea volumetric;

8. Phetoho ea torque e nyenyane, ho leka-lekana ho phahame, ho sisinyeha ho nyenyane, 'me ts'ebetso e tsitsitse, e le hore ts'ebetso e be bonolo ebile e le bonolo ho hlokomela automation;

9.Likarolo tse fokolang tse tsamaeang, ha ho na mochine o lumellanang, sebopeho se bonolo, boholo bo fokolang, boima bo bobebe, likarolo tse fokolang, ho tšepahala ho phahameng, le nako ea bophelo ea lilemo tse fetang 20.

Sbasebetsi ba Compressor Units

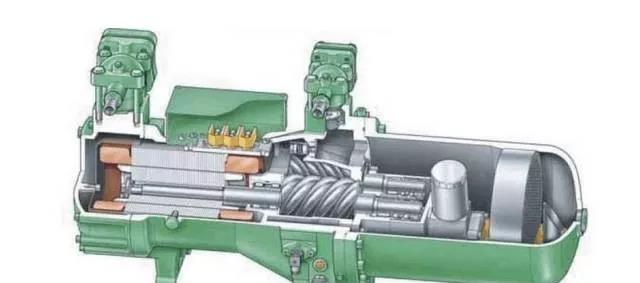

Molao-motheo:Ka ho qoelisoa ka bobeli ha li-rotor tsa Yin le Yang le motsamao o tsoelang pele oa mohala oa ho ikopanya le sebaka ho tloha pheletsong ea ho hula ho isa pheletsong ea ho tsoa, molumo oa "primitive" o fetoloa nako le nako, ka hona o phethela ts'ebetso e tsoelang pele ea ho hula le ho tsoa.

Sebopeho:E entsoe ka casing, screw (kapa rotor), bearing, sesebelisoa sa ho fetola matla, joalo-joalo.

Molemo:

1. Likarolo tse fokolang, likarolo tse fokolang tsa ho roala le ho tšepahala ho phahameng;

2. Ts'ebetso le tlhokomelo e bonolo;

3. Ha ho na matla a inertial a sa leka-lekanang.Ts'ebetso e boreleli le e sireletsehileng, ho sisinyeha ho tlase;

4. E na le litšoaneleho tsa ho fana ka moea o qobelloang, molumo oa ho qeta o batla o sa amehe ke khatello ea ho qeta, 'me maemo a sebetsang a fetoha;

5. Leino la rotor holim'a "screw compressor" le na le lekhalo.Ka hona, ha e utloe bohloko ho stroke se metsi mme e ka mamella ho sisinyeha ha metsi;

6. Mocheso oa mocheso o tlaase o tlaase, 'me o ka sebetsoa tlas'a tekanyo e phahameng ea khatello;

7. E khona ho lemoha phetoho e se nang mehato ea boemo ba sehatsetsing, ho amohela mochine oa valve o thellang, e le hore matla a sehatsetsing a ka lokisoa ntle le mehato ho tloha ho 15% ho ea ho 100%, ho boloka litšenyehelo tsa ts'ebetso;

8. Ho bonolo ho elelloa boiketsetso mme o ka hlokomela puisano e hole.

PIston Compressor Units

Molao-motheo:Ho itšetleha ka motsamao o phetoang oa piston ho hatella khase ka silindara.Hangata ho potoloha ha "prime mover" ho fetoloa motsamao o fananang oa piston ka mochini o kopanyang oa crank.Mosebetsi o entsoeng ke crankshaft bakeng sa phetoho e 'ngoe le e' ngoe e ka aroloa ka mokhoa oa ho noa le mokhoa oa ho qeta ho hatella.

Sebopeho:Ho kenyeletsoa 'mele, crankshaft, kopano ea molamu o kopanyang, kopano ea piston, valve ea moea le kopano ea li-cylinder liner, joalo-joalo.

Molemo:

1. Boemong ba khatello e akaretsang, litlhoko tsa lisebelisoa li tlaase, 'me lisebelisoa tse tloaelehileng tsa tšepe li sebelisoa haholo, tse bonolo ho li sebetsana le ho theola litšenyehelo;

2. Ho sebetsa hantle ha mocheso ho batla ho phahame.Ka kakaretso, katleho ea adiabatic ea lihlopha tse kholo le tse mahareng li ka fihla hoo e ka bang 0.7 ~ 0.85;

3. Matla le litšoaneleho tsa khase ha li na phello e fokolang mosebetsing oa compressor, 'me compressor e tšoanang e ka sebelisoa bakeng sa likhase tse fapaneng;

4. Compressor ea piston e batla e hōlile ka theknoloji, 'me e bokelletse phihlelo e ruileng ea tlhahiso le tšebeliso;

5. Ha molumo oa moea o lokisoa, ho ikamahanya le maemo ho matla, ke hore, moeli oa ho qeta o pharaletseng, 'me ha o amehe ke boemo ba khatello,' me o ka ikamahanya le maemo a mangata a khatello le litlhoko tsa matla a pholileng.

Nako ea poso: Dec-27-2021